In today’s market, counterfeit products remain a persistent issue, harming consumer interests and severely damaging brand reputation and market share. Therefore, effective anti-counterfeiting solutions are crucial. This article highlights several advanced anti-counterfeiting technologies, including hologram labels, QR code verification systems, and micro-nano sticker.

Hologram label anti-counterfeiting is a traditional yet widely applicable technology with unique advantages.

Technical

Based on laser holography, laser labels are produced using laser color holographic plate-making and embossing techniques. They exhibit three-dimensional, dynamic, and color-shifting effects, displaying different patterns and colors when viewed from various angles, creating a strong visual impact.

Pros and Cons

Pros: Mature technology with striking visual effects that attract consumer attention.

Cons: As technology evolves, laser labels face increasing risks of imitation, necessitating continuous upgrades.

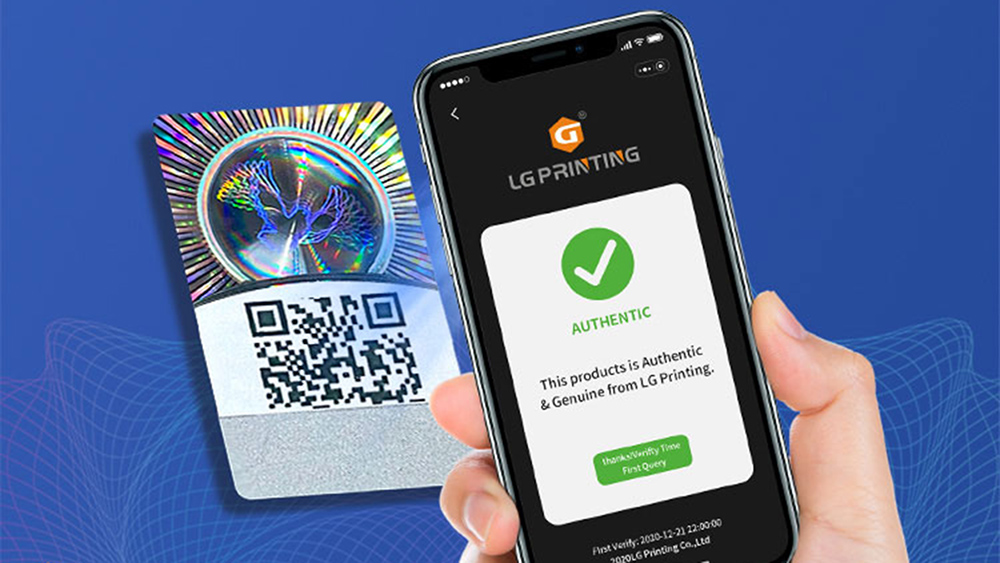

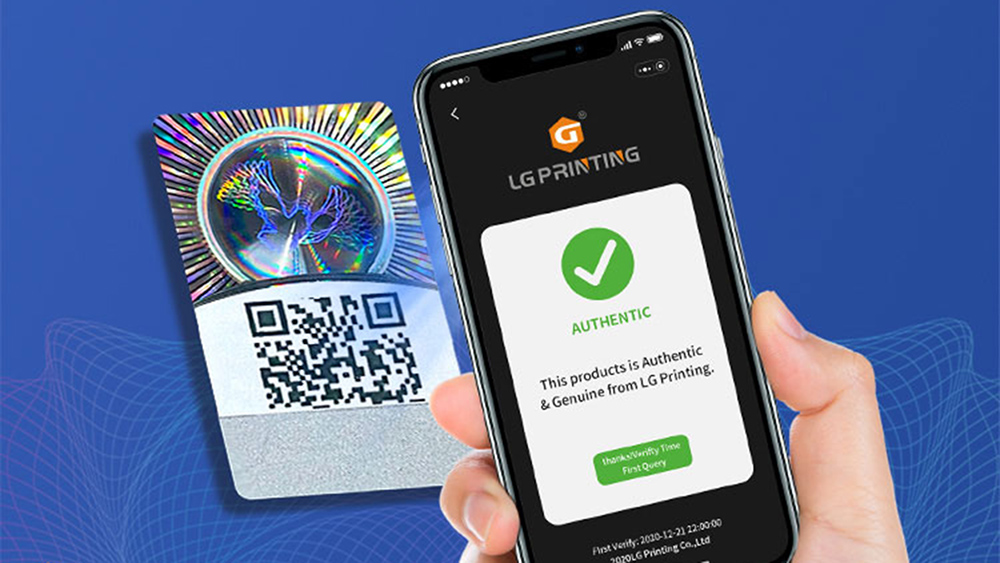

A digital anti-counterfeiting solution leveraging QR/barcode technology.

Code Generation Module: Assigns a unique identifier to each product.

Database Management: Stores product details (e.g., batch number, material source, inspection reports).

Verification Module: Compares scanned codes with database records via smartphones and returns results to users.

Usage

Consumers scan the QR/barcode on packaging to verify authenticity and access product information. Companies also use this system for market research and targeted marketing. For instance, a beverage brand may analyze purchase data (region, time) to refine R&D and marketing strategies.

Advantages and Challenges

Pros: User-friendly, real-time verification, and robust data analytics for businesses.

Micro-nano sticker, a cutting-edge solution, offer unparalleled advantages and broad application potential.

(1) Technical Principle

Micro-nano tags utilize micro-nano fabrication to create structures at micrometer (1µm = 1/1000mm) and nanometer (1nm = 1/1000µm) scales. Their unique optical, electrical, or magnetic properties make replication nearly impossible. For example, nanoimprint technology produces ultra-precise patterns beyond conventional printing capabilities.

(2) Key Features

High Precision/Resolution: Nano-scale patterns with intricate details detectable only via spe.cialized equipment.

Unique Physicochemical Properties: Customizable optical/electrical responses (e.g., specific light interactions) for multi-layered security.

Uncopyable: Complex proprietary manufacturing deters forgery.

Multifunctional: Integrates sensors (e.g., temperature/humidity monitoring) or data storage for enhanced utility.

(3) Applications

Luxury Goods: Ideal for high-end brands (e.g., jewelry) to verify authenticity under spe.cialized light/device.

Pharmaceuticals/Food: Ensures safety by tagging packaging with batch/expiry data.

Electronics: Tracks components (e.g., smartphone batteries) to prevent fakes and log usage history.

(4) Market Edge and Future Outlook

Advantage: Superior security outperforms traditional methods in counterfeit-prone markets.

Future: Falling costs and integration with IoT/big data will enable real-time tracking and smart anti-counterfeiting.

As anti-counterfeiting demands grow, businesses must adopt integrated solutions. hologram labels, QR systems, and micro-nano sticker each offer unique protections, with micro-nano stickerstanding out for innovation and scalability. Companies should tailor strategies to product needs, combining technologies to safeguard brands and consumers. With advancing technology, future solutions will further enhance market security and trust.